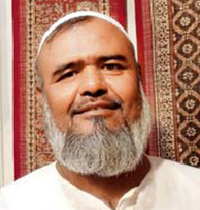

Khatri Mohammed Yusuf

![]() Art Form:

Art Form:

Bagh Print

![]() Contact No:

Contact No:

09425486307

9770427777

9713873656

9575891786

![]() Home Address:

Home Address:

Dhar Road, Bagh, District Dhar, Madhya Pradesh, India

![]() Award:

State Award - 1999, National Award - 2003, Shilp Guru Gold Medalist - 2017, Seven time International Award for Excellence for UNESCO & WCC - 2014-2012-2007-2004, World Craft Council Award for Excellence (WCC) - 2014

Award:

State Award - 1999, National Award - 2003, Shilp Guru Gold Medalist - 2017, Seven time International Award for Excellence for UNESCO & WCC - 2014-2012-2007-2004, World Craft Council Award for Excellence (WCC) - 2014

Bagh Print in its started in 1962 when a group of Muslim Khatri artisan, originally from Sindh (now in Pakistan ), and had migrated to Marwad in Rajasthan and then to Manawar. With them they brought the block printing technique, which is now the unique Bagh printing style. Cotton, Silk cloth is treated in a traditional mixture of Corrosion of Iron, Alum and Alizarin. Traditional designs are filled by hand by highly skilled craftsmen. The finished cloth is washed in flowing river water and sun dried for a perfect finish. The design repertoires of Bagh Print cover geometrical and floral compositions in predominant red and black colour. These motifs include Nariyal Zaal, Ghevar Zaal (Taj Mahal Paintings Designs), Saj, Dakmandwa, chameli or jasmine, maithri or mushroom, leheriya and jurvaria or small dots on the field. In the Bhatti process, materials such as cotton , tussar, silk and crepe are soaked overnight, then dried. In a cement tub, a paste is made of goats droppings, raw salt or sanchura, castor oil and water. The fabric is soaked in this paste by stamping it. The fabric is dried in layers on a sloped surface to allow the water to drain. Then it is once again washed, and is then ready for printing. For printing, a wooden tray which is called a Paliya in the regional language is prepared with a bamboo jali fitted in, on which black or red paste is applied. Over this, layers of thick wet cloth are placed which soak in the colours. The block is then dipped into it and placed with a light touch on the fabric which is stretched on a table with a stone slab covered with seven layers of jute. Once the printing is done, the sari is dried and kept aside for eight days. The final stage is to rinse the cloth under the running water of the Baghini. Thereafter, it is dried again and put in the bhatti mixed with dhawadi flowers (wood fordia fruticosa) and Alizarin (root of Morinda Tinctoria). Tapai and drying follow. And finally, the Bagh print textile is ready.![]() Note:

Note: